Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Jiaozuo Huafei Electronic & Electric Co., Ltd. ZhongKuang (Hainan) Technology Co., Ltd.

ginger@jzhfdq.com

+86-391-3567086

Model No.: belt conveyor system control

Applicable Industry: Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Morocco, Kenya, Chile, Romania, Ukraine

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, United States, Philippines, Pakistan, India, Mexico, Russia, Morocco, Kenya, South Korea, Colombia, Sri Lanka, Kazakhstan, Uzbekistan, Australia

Status: New

Warranty Period: 1 Year

Transportation: Ocean,Land,Air

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

The Solution of Conveyor System Based on Intelligent Mine

Application scope

The solution integrates intelligent control for Belt Conveyor system, telephone dispatching and video surveillance of, and constructs a complete dispatching, operation and monitoring network system. It can not only improve the production efficiency of equipment with safety, save resource consumption, reduce the operation personnel, but also realize the unattended and intelligent operation of the belt conveying system. It is suitable for the comprehensive requirements of intelligent control and management upgrading of underground and surface belt conveyors and their related subsystems. It is a customized solution for high-end customers who meet the requirements of unattended system and intelligent operation of mines.

Main functions

The solution takes the safety, reliability and intelligence level of intelligent control of conveyor system as the core, taking real-time detection and monitor the key information of main equipment and hoist process, remembering the faults, remotely transmitting and storing the data and information, intelligently analyzing and specialized processing the invisible fault information. Fully realize the self-diagnosis of equipment and system, explicit fault alarming, invisible fault warning and so on, supporting the uploading of management information and control command transmission. With the intelligent function of "system plug-in", which is convenient to realize the information interaction with other information systems to meet the needs of the realization and operation of intelligent mines.

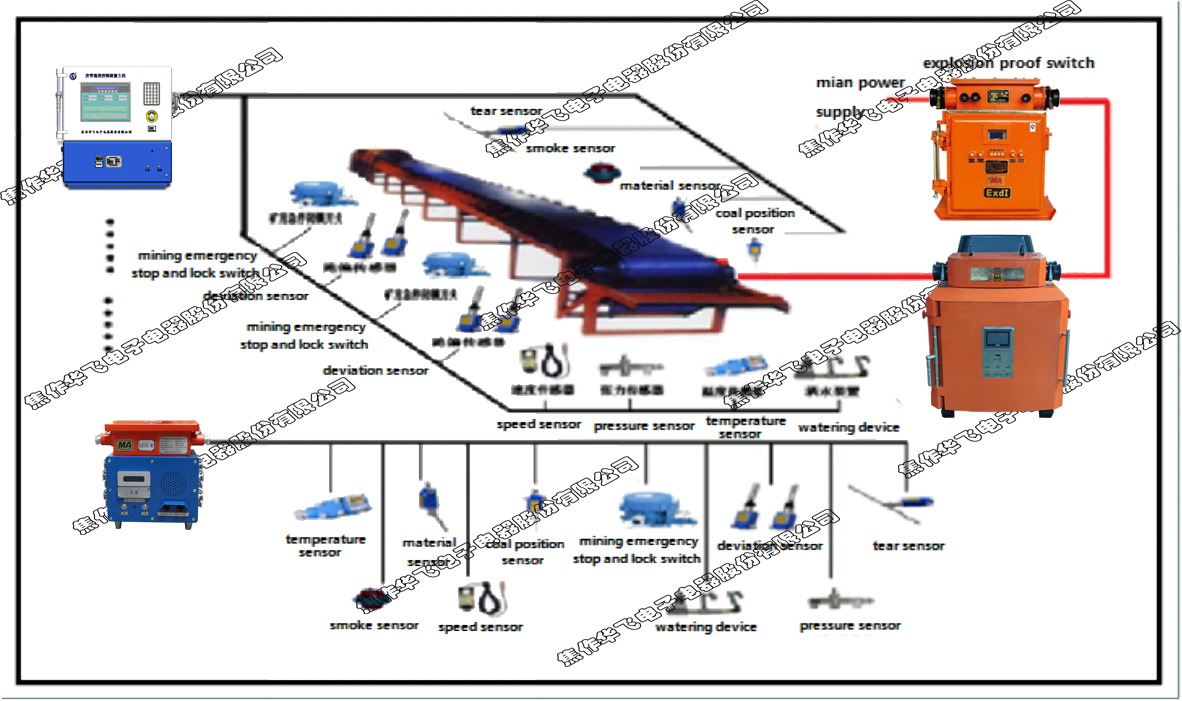

Schematic illustration of Belt Conveyor Control and protection

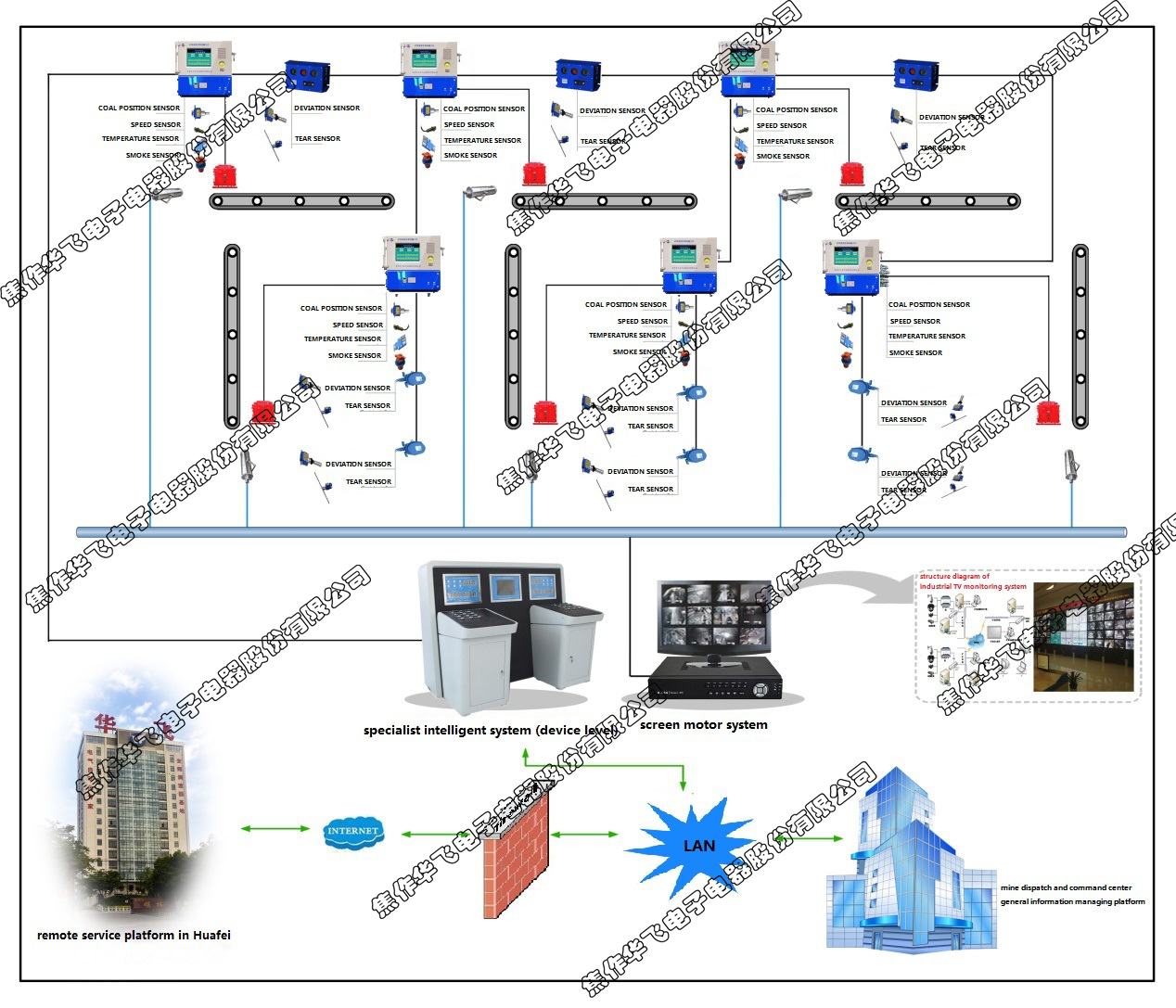

“5+1+2” Intelligent Control Solution for Conveyor System

This scheme has two sets schemes of underground and surface by considering environment. The main difference between these two schemes are explosion proof and protection grade caused by the environment of using equipment, the other main control functions and performance are basically the same.

“5+1+2” scheme include

This scheme includes the Conveyor Automation control system, conveyor energy consumption management system, conveyor expert intelligent system (equipment level), audio communication system, video surveillance system, network communication and data remote transmission channel, dispatching management and monitoring platform, remote service platform consisting of five subsystems, one channel and two support platforms.

1. Conveyor Automation Control System

The conveyor Automation control system takes the high performance PLC as the core control device, and the single belt Conveyor Control takes the embedded single chip microcomputer as the core control device. The whole system runs in the high efficiency and low consumption mode of "start with coal, stop without coal, fast with more coal, slow with less coal", which has the characteristics of advanced technology, stable performance, safe and reliable, good economy and low energy consumption. By collecting and processing the working condition information of each sensor in real time, the operation condition of the equipment is accurately judged, it also has the functions of communication, control, protection, fault location, animation display and voice alarm. It can meet different special control and communication requirements at user site.

2. Conveyor Energy Consumption Management System

The actual load of each conveyor belt is accurately measured through professional and reliable detection and a complete intelligent control algorithms. Taking the belt conveyor system as a whole, the system adjusts the running speed of each belt machine, so that it runs in the high efficiency mode of "start with coal, stop without coal, fast with more coal, slow with less coal".

3. Conveyor expert intelligent system (equipment level)

Mainly include: hardware facilities of industrial control computer, displayer, special collection card, communication network, as well as application software packages of monitoring software expert think tank. The main software function modules include equipment management module, equipment condition monitoring module, fault information management module, system condition reproduction module, expert think tank module, Remote Diagnosis module.

4. Audio Communication System

The voice call requirements along the conveyor line are easily solved through the intrinsically safe amplifying telephone (including emergency stop) installed along the system.

5. Video Surveillance System

Load point, transfer point, unloading point, crusher, coal bunker, workstation and other place needs monitoring;

6. Network communication and data remote transmission channel

The signal is transmitted to the dispatching command center through LAN to provide hardware and software interface support.

7. Dispatching management and monitoring platform

If the dispatching system has application software, data interaction can be carried out directly after shaking hands approved by both parties. If there is no application software, the application software can be provided to realize the application requirements.

8、Remote service platform

Remote service platform support system (Locate in Jiaozuo, Henan Province, serving national customers): based on reliable network security mechanism support to achieve remote diagnosis of equipment and other intelligent functions through the public network. Remote detection and high-quality service is available for hoist, belt conveyor, main ventilator and other large mine equipment.

Underground schematic block diagram

Main Function Module of "Expert Intelligent Software System" in Conveyor System

Module 1 "Equipment Conditions Monitoring Module"

To detect at real-time, record and monitor the working condition of the system equipment in the field through safe and reliable technical means, and the state information of the equipment is displayed in a dynamic and intuitive way.

Power supply system: voltage, current, power, power factor, fault information;

Conveyor motor drive equipment ( VFD and soft starter): voltage, current, power, power factor, fault information, etc;

The three-dimensional mechanical vibration, bearing temperature of motor, gearbox and other main mechanical and electrical equipment;

Tension detection and adjustment of tension controller, working state of reverse stop;

Hydraulic and brake control: pressure, pressure difference, oil temperature, oil quality, gate clearance, etc;

The running state, running speed, transportation quantity, signal state and running direction of each conveyor in the system;

Module 2 "Fault Information Management Module "

Once a functional index is abnormal during the operation, the module will record such information in time, and the information will be saved for up to six months. For example: the fault information of the motor, gearbox, speed controller and other major equipment related to conveying system, and emergency stop, skid, over speed, deviation, broken belt, longitudinal tear, transverse tear, stack, full bunker, over temperature, smoke, tension fault related to each conveyor. It has clear and perfect fault location function, which can easily find fault points to eliminate fault easily and resume operation in time.

Module 3 "Energy Consumption Management Module"

Through the combination measures of infrared detection and current judgment, the actual material carrying capacity of each conveyor in the system is judged more accurately, and the running speed of each conveyor is comprehensively judged and effectively controlled to ensure that the system runs in the high efficiency mode of "start with coal, stop without coal, fast with more coal, slow with less coal" which can save electricity consumption to the maximum and reducing the invalid loss of equipment.

Module 4 "System Condition Recurrence Module"

This module is the front module of the conveyor system expert think tank. According to the need of problem analysis, the user can select operation condition recurrence of a single or multiple equipment at the corresponding fault time. This function greatly facilitates the analysis of the cause of equipment failure, helps to find the reason, and eliminate the deep causes in the equipment and management.

Module 5 "Expert think tank module "

The module mainly for making statistics, classifying, concluding and analyzing the fault information during machine operation, potential fault information, consciousness fault information and so on, making comprehensive analysis and judgment with the help of expert experience or previous processing experience. To provide support for the intelligent operation of the equipment, expert diagnosis, troubleshooting and so on, to make comprehensive analysis and prediction according to the potential fault information, to provide early warning information for the machine operation.

1) explicit fault monitoring module. (previous fault information monitoring, report analysis, etc.)

2) hidden fault prediction module. (potential fault analysis and prediction, etc.)

Module 6 "Equipment Management Module "

Establish equipment files, equipment overhaul and daily maintenance information, and manage the main information in the whole life cycle of the equipment.

Product Categories : Belt Conveyor Control System

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.