Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Jiaozuo Huafei Electronic & Electric Co., Ltd. ZhongKuang (Hainan) Technology Co., Ltd.

ginger@jzhfdq.com

+86-391-3567086

Model No.: GEJ20

I. Overview

1. Product application and usage range

The sensor is used for the place under coal mine with coal dust and methane explosive gas, and is used to detect the deviation of Belt Conveyor.

2. Product features

The sensor has reliable performance, simple structure, good safety performance, and easy to use and other characteristics.

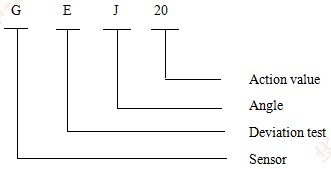

3. Product Model and Significance

Explosion-proof type of sensor: Mining intrinsically safe type ExibI Mb

Sensor Model Explanation

4. Related devices

The related device of the sensor is KHP121A-Z coal mine explosion proof and intrinsically safe type controller of Belt Conveyor Protection device.

5. Ambient condition

5.1 Normal working condition

a) Altitude less than 2000m.

b) Ambient temperature within -10℃~+40℃.

c) Relative humidity not over 95% (25℃).

d) The place under mine with coal dust and methane explosive gas.

e) The place without corrosive gas which could damage metal and insulation.

5.2 The worst ambient condition of storage and transportation.

a) High temperature: +60℃.

b) Low temperature: -40℃.

c) Relative humidity not over 95% (25℃).

d) Vibration: accelerated speed 50m/s².

e) Impact: peak accelerated speed 500m/s².

II. Technical features

1. The technical parameters of the sensor are shown in table 1

table 1

| Item | Performance and parameters |

| Contact mode | One pair of normal open, one pair of normal close |

| Contact capacity | DC 12.5V/0.5A (resistive load) |

| Action levels | I level |

| Action direction | Universal |

| Action angle | 20 ±3° |

| Reset angle | 5°~10° |

| Limit rotation angle of the feeler lever | 45° |

| The action force of the feeler lever | 20 N~100N |

| Contact resistance | ≤0.1Ω |

III. Structure features

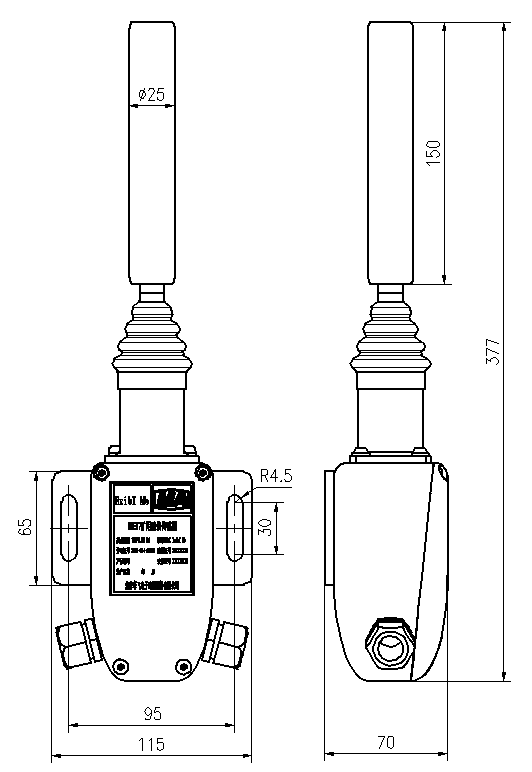

The structure of deviation sensor is shown in below figure. This sensor is mainly composed of feeler lever, shell and internal wiring device. It is with reliable performance and easy to use. Size: 115mm×70mm×377mm. shell material: PA plastic. Weight: 2.5kg

IV. Working Process and Principle

When the belt deviates, the edge of the belt pushes the feeler lever to tilt. When the angle of inclination >20°, the internal switch is closed, indicating that there is a belt deviation. Stop the conveyor operation through the controller. After the belt is reset, the feeler lever can be reset automatically.

V. Installation and wiring

Install the sensor on the appropriate place according to the actual situation, and the deviation sensor should be fixed on both sides of the belt. In principle, one piece should be installed on each 30~50 meters. Installation should ensure that it is not easy to take misoperation and the action is reliable.

Cable outer diameter φ8~φ12( or communication cable is available), not less than 2.5mm².

VI. Usage attention

1. The structure and every electrical parameters of the sensor have been debugged before leaving the factory, the user shall not change its structure and electrical parameters at will to ensure the performance of protection, explosion-proof and intrinsically safe. This product can only be used with designated device, or the devices have explosion proof tested.

2. The deviation detection of the conveyor is determined by the sensor, and the sensor is installed after debugging, the working condition of the sensor directly determines whether the deviation protection of the control device can work, and the non-professional personnel is not allowed to take off or install the sensor.

3. The maintenance personnel should regularly check the condition of each part of the sensor, the problems must be dealt with in time.

4. The improper changes of internal components wiring may cause equipment damage, our company does not bear the liability and economic losses caused by above-mentioned accident.

5. The packing carton can be used for all kinds of transportation including land and water under the condition of avoiding direct rain and snow.

6. The packaged device can be stored in the warehouses with air circulation, the temperature is (-10~40)℃, relative humidity not over 90% for more than 12 months.

7. Take out the packing list and compare with each item to confirm the conformity.

8. To check the nameplate on the sensor is comply with the order requirement.

Huafei Company could provide Different Kinds Of Sensors, such as complete Automatic Control Sensor, Mining Temperature Sensor for belt conveyor, belt conveyor automatic control sensor, Belt Conveyor Safety Protection, Belt Conveyor Sensor, Explosion Proof Sensor, Belt Conveyor Sensors and other Belt Conveyor Safety Protection.

Product Categories : Electric Aotumation > Belt Conveyor Control

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.