Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Jiaozuo Huafei Electronic & Electric Co., Ltd. ZhongKuang (Hainan) Technology Co., Ltd.

ginger@jzhfdq.com

+86-391-3567086

Model No.: GQG5

Payment Type: L/C,T/T

Incoterm: CFR,CIF,FOB,EXW,Express Delivery

I. Overview

1. Product application and usage range

The sensor is used for the place under coal mine with coal dust and methane explosive gas, and is used as the smoke protection of Belt Conveyor.

2. Product features

The sensor has reliable performance, simple structure, good safety performance, and easy to use and other characteristics.

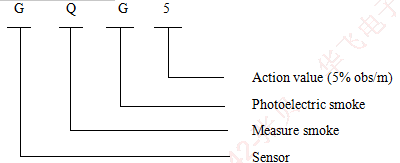

3. Product Model and Significance

Explosion-proof type of sensor: Mining intrinsically safe type ExibI Mb

Sensor Model Explanation

4. Related devices

The related device of the sensor is KHP121A-Z coal mine explosion proof and intrinsically safe type controller of Belt Conveyor Protection device.

5. Ambient condition

5.1 Normal working condition

a) Altitude less than 2000m.

b) Ambient temperature within -5℃~+40℃.

c) Relative humidity not over 95% (25℃).

d) The place under mine with coal dust and methane explosive gas.

e) The place without corrosive gas which could damage metal and insulation.

5.2 The worst ambient condition of storage and transportation.

a) High temperature: +60℃.

b) Low temperature: -40℃.

c) Relative humidity not over 95% (25℃).

d) Vibration: accelerated speed 50m/s².

e) Impact: peak accelerated speed 500m/s².

II. Technical features

1. The technical parameters of the sensor

1.1 Detection principle: photoelectric smoke.

1.2 Rated voltage: DC 12V ( sensor is working normally within 11 V~13.6V).

1.3 Max current: ≤100mA.

1.4 Action condition: smoke concentration≥5% obs/m.

1.5 The action sensitivity is III, the response time ≤20 s.

1.6 Output signal : detecting without smoke ≥ 10V DC, alarming with smoke ≤ 0.5 V DC.

2. Sensor working duty: uninterrupted duty.

3. Major functions:

The smoke sensor is in monitoring status on the circumstance of conveyor running normally, and the output voltage is 12V high voltage. After connecting to the control device, the smoke protection circuit of the control device does not operate. When the roller and the belt of the conveyor slip, making smoke by friction, the output voltage of the smoke sensor becomes 0V, the smoke protection circuit of control device takes action, so that the conveyor stops for smoke protection.

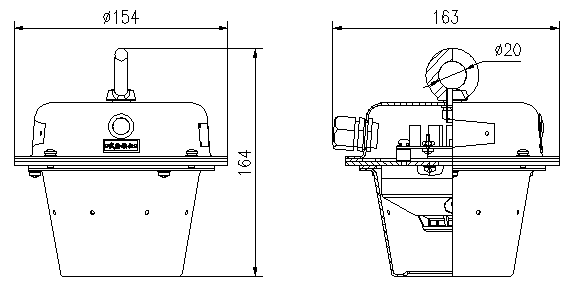

III. Structure features

The external of smoke sensor is shown in below figure 1. The lifting ring is on the sensor top for hanging. The circuit board is fixed in the shell, the photoelectric smoke fire detector is installed in the lower part, if the wind is over 5m/s, the wind shield is required to install out side the smoke detector. This sensor shell is made of stamping steel plate 1.5/SC1. Shell material: Q235A. Weight: 2.3kg

Figure 1 Smoke sensor external

IV. Working Process and Principle

When smoke occurs in the tunnel due to belt friction or other reasons, the smoke sensor hanging at the top of the tunnel acts, the output voltage becomes 0V, the smoke protection circuit in the control device acts, cutting off motor power supply to stop the conveyor, completing smoke protection.

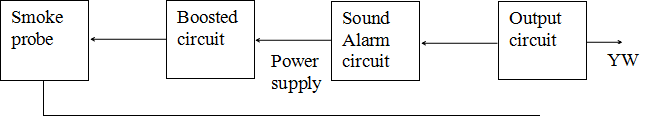

The figure 2 is the working process and principle.

The circuit of smoke sensor consists of smoke probe circuit, boosted circuit, output circuit and sound alarm circuit.

The circuit principle block diagram consists of the following parts:

Figure 2 Working process and principle block

Since the smoke probe is powered by 20~24 V, but the power supply is 12V, so the boost circuit is designed to turn 12V power supply into 24V power supply for probe. Boosted circuit is mainly composed of D1 and peripheral components. It is a voltage doubling rectifier circuit. D1 and R2、C3 constitute the oscillators, terminal 3 is the output end, when the terminal 3 goes down, G(+12v end) charges for C2 through V2 and terminal 3, it is similar to the voltage of power supply, when the terminal 3 goes up, the outputting 12V is superimposed by terminal 3 and C2, charging for C1 through V1, it is about 2 times the power supply voltage for the probe. The terminal 4, 8 and 1of D1 are the terminal of power supply.

The output circuit consists of T1 and peripheral components. T1 is turnoff at static, Relay K doesn't work, G making the end YM outputting high potential through the normally closed contact K1-1b. The R5 is set to reduce the leakage current, V6 is set to protect T1, which can absorb the overvoltage caused by the relay breaking. When there's a smoke alarm, the circuit in the smoke probe is on, voltage drop on the R1 increases, T1 is on, relay K is connecting, K1-1b disconnects, K1-1a connects, YW outputs low potential. C1 is filter capacitance.

A sound alarm circuit consists of D2 and peripheral components. D2-A and R3, C4 constitute an audio oscillator (approximately 3 KHZ), output through a drive circuits consists of D2-B, D2-C, D2-D making YD sound, D2-F and R4、C5 constitute a modulation oscillators, modulate the audio oscillator through V4, making YD sound intermittent alarm. D2-E control the vibration of D2-A. The input end of the D2-E is connected to the YW output end. YW is high potential at static, D2-E output is low potential, V3 turns on to make the D2-A stop. After smoke alarm, the YW output low potential, the output of D2-E become high potential, V3 turns off, D2-A start to vibrate, YD sound the alarm.

V. Installation and wiring

Hangs the smoke sensor on the conveyor head at the 5-6m rear at downwind direction to guarantee it can work immediately when there are smoke caused by the main roller friction. If the wind speed is over 5m/s, the wind shell is required to be installed, if the wind speed is less than 5m/s, the wind shell is not necessary. The power supply of smoke sensor (G,0) is powered by control device or single power box, connect the output end YW to the smoke protective input end of the control device. Shown as below:

VI. Usage attention

1. The structure and every electrical parameters of the sensor have been debugged before leaving the factory, the user shall not change its structure and electrical parameters at will to ensure the performance of protection, explosion-proof and intrinsically safe. This product can only be used with designated device, or the devices have explosion proof tested.

2. The smoke protection is determined by the sensor, and the sensor is installed after debugging, the working condition of the sensor directly determines whether the system control can work, and the non-professional personnel is not allowed to take off or install the sensor.

3. The maintenance personnel should regularly check the condition of each part of the sensor, the problems must be dealt with in time.

4. The improper changes of internal components wiring may cause equipment damage, our company does not bear the liability and economic losses caused by above-mentioned accident.

5. The packing carton can be used for all kinds of transportation including land and water under the condition of avoiding direct rain and snow.

6. The packaged device can be stored in the warehouses with air circulation, the temperature is (-10~40)℃, relative humidity not over 90% for more than 12 months.

7. Take out the packing list and compare with each item to confirm the conformity.

8. To check the nameplate on the sensor is comply with the order requirement.

Huafei Company could provide Different Kinds Of Sensors, such as complete Automatic Control Sensor, Explosion Proof Sensor, Mining Temperature Sensor for belt conveyor, Belt Conveyor Safety Protection, Belt Conveyor Sensor, belt conveyor automatic control sensor, Belt Conveyor Sensors and other Belt Conveyor Safety Protection.

Product Categories : Electric Aotumation > Belt Conveyor Control

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.